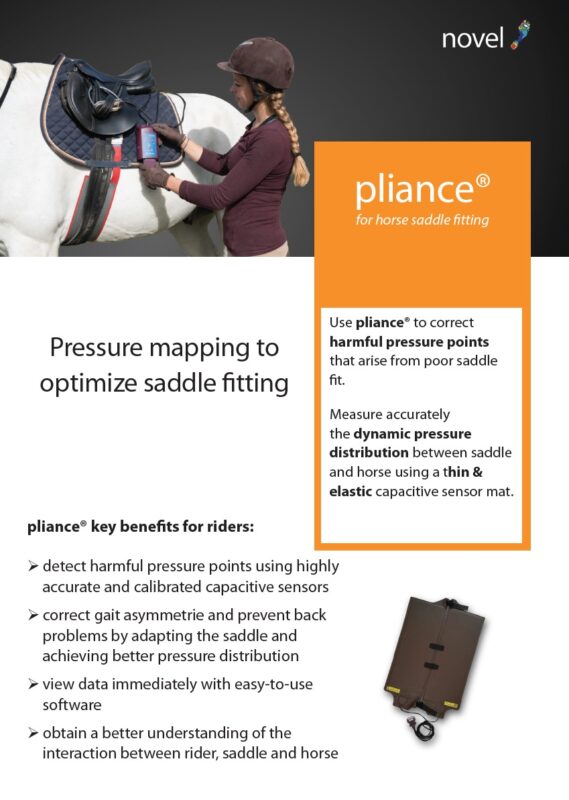

pliance® – Pressure and load distribution on hard or soft surfaces

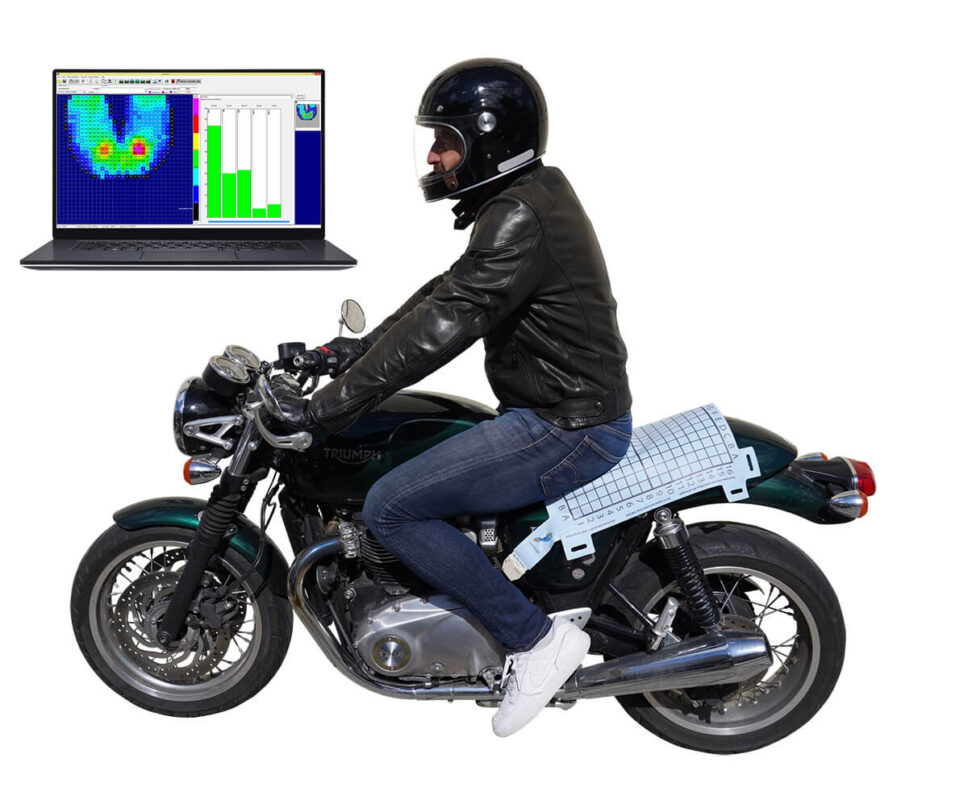

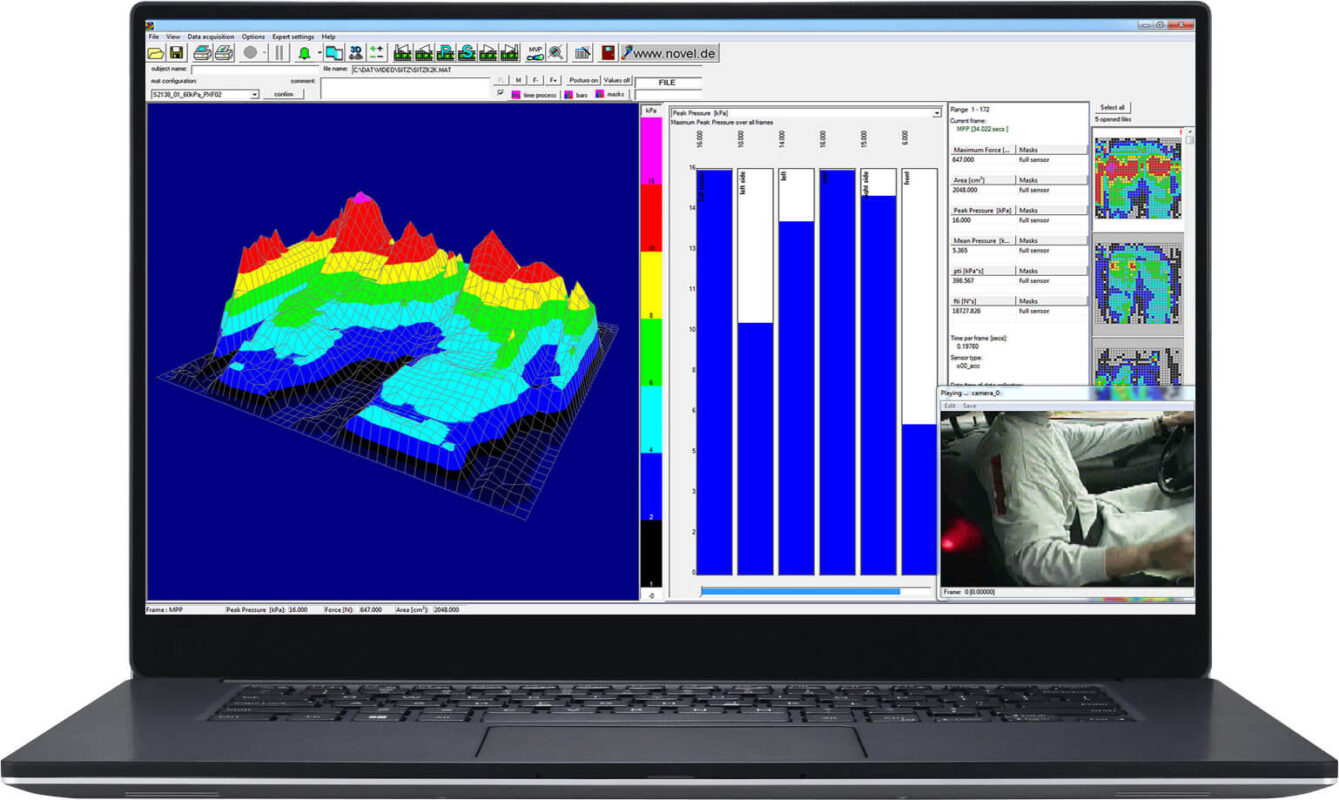

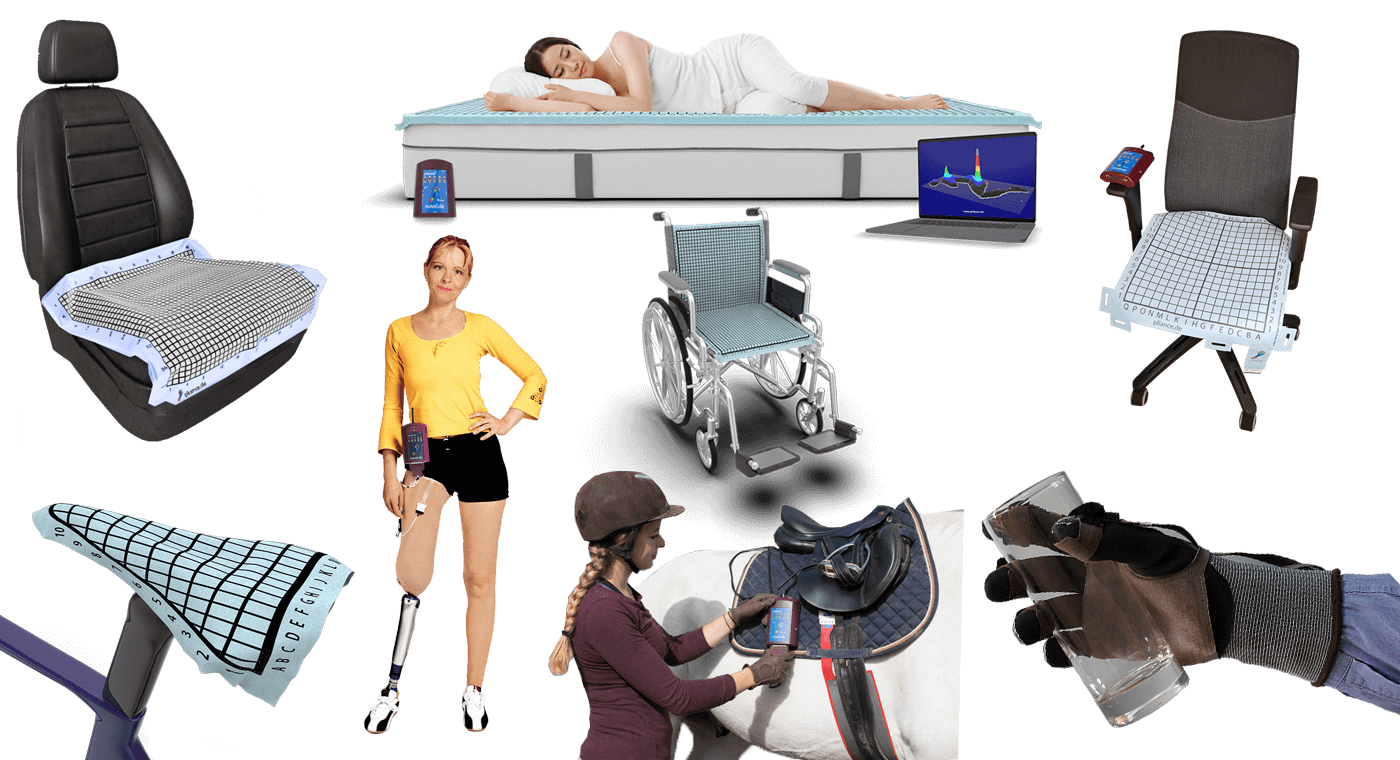

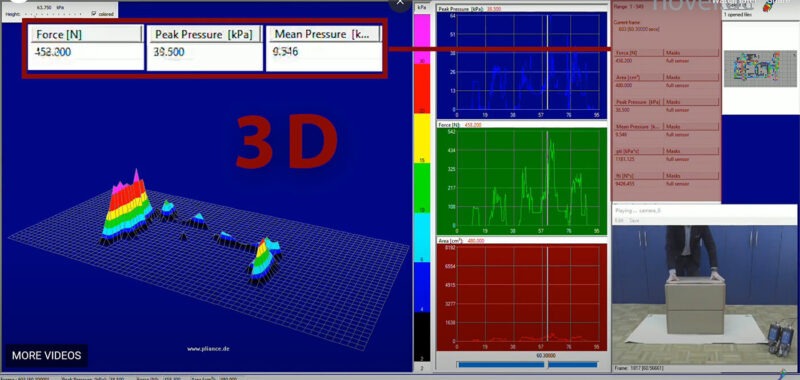

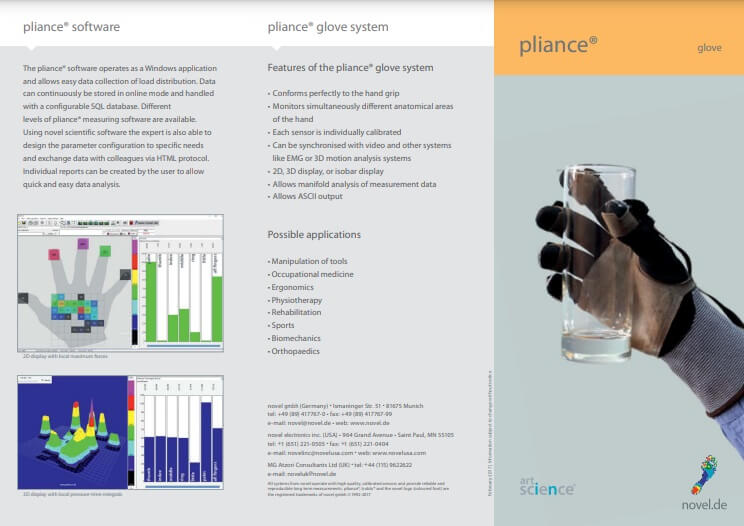

pliance systems* offer the state of the art technology for pressure distribution measurement between hard, soft and curved surfaces. The systems consist of a flexible and elastic measuring sensor mat, a multi-channel analyser, a calibration device and a software package for PC.

Two kinds of pliance analysers are available: The pliance-xf-16 device scans an array of up to 16*16 sensors, while the pliance-xf-32 device scans larger sensor arrays with up to 32*32 sensors, which is typical for larger seat mats and special high-resolution sensor mats. A master-slave synchronisation of two pliance-xf-32 device allows to operate even more complex configurations, for instance sensor mats to cover bed mattresses.

novel developed an analyser technology that allows not only individual calibration curves for each sensor, but also individual dynamic amplification control and crosstalk suppression, resulting in very accurate and reproducible pressure values. The pliance analyser communicates with the PC via Bluetooth, or alternatively via fibre optic/USB interface. For recordings independently from PC the system can be triggered manually and record data on SD card.